This is the second in a series of blog posts that are based on some writing I did in the late-1980′s and a lot of thinking I have done since. Click here to read the first post.

Chapter One – The System

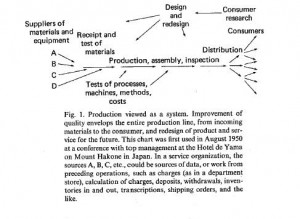

W. Edwards Deming was among the first prominent systems thinkers in the US. As shown in the illustration above from page 4 of his book Out of the Crisis, Deming instructed managers to include every aspect of manufacture when they strive to improve the quality of their product. Deming was specifically battling the pervasive notion that defects resulted from poor workmanship, that is, the poor performance of individual workers. Deming made the point that, in fact, quality depends on the tools and equipment, raw material, plant layout and other factors, all of which are management’s responsibility and none of which are under the control of individual laborers. Moreover, Deming urged managers to work closely with workers, suppliers, customers, and competitors to encourage innovation, productivity, and higher quality.

Before exploring Deming’s ideas further, we need to think about what the components of “the system” of our personal lives might be.

The starting place is to identify a product. I will hazard a guess that most people, if asked the (somewhat bizarre) question, “What, in your life, would you regard as ‘your product’?” would respond with something about their work or their career. I disagree. I believe that

our products are our personal relationships.

Using this metaphor, we create new products or build on existing products each day. Most of us also have a huge range of product—everything from a committed spousal relationship to the relationship we have with the friendly cashier at the neighborhood store, from a parent-child relationship to the relationships we create when we nod or smile at someone we pass on the sidewalk.

For those of us who lack the inventiveness or genius of Edison or Einstein, our only enduring legacy will likely be the quality of our relationships. Deming’s approach to improving the quality of manufacturing can, with some adaptation, provide excellent guidance on how to improve the quality of our relationships.

From Deming’s flow chart above, we can identify the components of the manufacturing system and find the counterparts in our own lives: management and labor, customers, suppliers, competitors, tools and equipment, raw materials, design and redesign. In pursuing this analogy, I hesitate to identify and segregate aspects of ourselves that are, in fact, not separable, but I feel there is value in doing so in this introductory phase.

MANAGEMENT AND LABOR

Management and labor appear implicitly in Deming’s illustration, and are central components of “the system” – those who make and implement decisions, use the tools and equipment, create the designs, make the product, and do the testing.

In a manufacturing context, management is the individual or group that makes the most far-reaching decisions for the company: What product will we manufacture? Where will we build our plant(s)? How will we treat our employees? We’ll see later that Deming further places on management the onus of answering questions like: What will we be doing in 10 – 15 – 20 years? What is our long-term reason for being?

We address similar questions in our own lives and you could say that there is some part of an individual that acts as “management.” If you have lived for any length of time (you probably need to reach beyond adolescence) and have given much thought to what’s important in your life, perhaps you have reached the same conclusion I have—that my relationships with other beings are the most important things to me.

With the help of Deming’s ideas, in some of my best moments, I view myself as being in the business of creating and building relationships, and continually improving the quality of those relationships. That is a decision that my inner “management” has made and it has had far-reaching implications.

Regarding labor – our labor force is simply our body; it carries out the decisions made by “management” and gives those decisions physical form. The body carries out verbal, non-verbal and written communication—the raw material of our relationships.

CUSTOMERS

If our products are relationships, then our customers are every being with whom we interact. Our family members are our regular customers; they “consume” a lot of our “product” and can be quite demanding and also aware of highs and lows in quality. For that reason they can be our best guides as to how our quality improvement efforts are progressing. But they are by no means our only customers. Since most of us spend much of our time at work, our co-workers may also be “regular customers.”

But our family members and those we work with still comprise only a fraction of our customer base (and for single, self-employed individuals, this fraction may not even exist). If relationships are our product, then every being (human, animal, plant and perhaps rocks, too) with whom we interact, no matter how tangentially, is a customer!

TOOLS, EQUIPMENT, MATERIAL

In the same way that a manufactured product requires certain raw materials, tools and equipment for its manufacture, so our relationships require items or concepts, including language, that can be considered analogous to materials or equipment. In addition, a particular item may not be required for a particular interaction, but it may have an influence on the quality of the relationship.

For example, suppose you’re walking down the sidewalk and someone in a car stops and asks your help with directions. I think most of us would interact differently with a young man in a t-shirt driving a pick-up than we would with the same young man in a business suit driving a Mercedes. We might use different language or be more or less likely to make eye contact or use many other variations. This illustrates that our material possessions—our home, car, clothing, and toys of all kinds—do affect our relationships.

Some of our material possessions can thus be considered “equipment” that we use in building our relationships. If the focus of our lives is our relationships, then “management” has another consideration besides price and other typical factors when deciding on a purchase—namely, its potential impact on significant relationships and regular customers.

DESIGN AND REDESIGN

Plan –> Do –> Study –> Act, the “PDSA Cycle,” was the foundation of Deming’s approach to continuing the improvement of product quality. We can use this concept to help repair and improve our relationships, too. Identify trouble spots, plan an approach to heal the pain, implement the plan (“do”), evaluate how well the plan worked (“study,” perhaps through meditation or journaling), then “act” on that better understanding to refine the plan, develop a new one, or apply it to a different product (relationship). Then repeat the cycle using the new or refined plan or the new application.

~

There are two other components in Deming’s system: suppliers and competitors. The concept of a supplier is sufficiently important that an entire blog post will be devoted to it. As for competitors, since our relationship with any individual is unique, for our purposes, there are no competitors.

The important thing to keep in mind is that all these components—management, labor, as well as equipment, material, suppliers, and customers—are, in Deming’s view, integrated into one holistic system, without barriers. So, our first task in implementing Deming’s principles is to be more inclusive as we think about how we interact with the beings around us, becoming aware of “the system” in which we operate.

In the next few posts, we’ll look at some of Deming’s “Fourteen Points for the Transformation of Management” and how they can help us improve our relationships. And our lives.