This is the first in a series of blog posts that are based on some writing I did in the late-1980’s and a lot of thinking I’ve done since.

The principles of W. Edwards Deming, developed to help transform the management of a manufacturing business, adapt remarkably easily to help transform the management of our lives. In this post, I present a brief history of Deming’s work and a broad outline of his basic principles.

Dr. Deming pioneered the idea of setting product or service quality as the top priority for any business. He developed guidelines to help a business continually improve the quality of its products or services.

During the early 1940s, W. Edwards Deming’s Ph.D. research focused on finding how to quantitatively measure and improve product quality. He and his mentor, Walter Shewhart, devised a means of determining whether fluctuations in any process of manufacture were due to random variation or systematic problems. This is important to know because random variation cannot be avoided whereas systematic variation indicates a problem that can be identified and rectified. The result of their work was “statistical process control” and is still widely used in many industries.

Under sponsorship of the War Department during World War II, Deming introduced these ideas to manufacturers of military equipment. It had become imperative to improve the quality of some items because American soldiers were being killed due to defective equipment.

Deming’s most notable success occurred after he was invited to Japan in the early 1950s. Deming instructed engineers and managers from some of Japan’s struggling companies in his philosophy of business and the nuts and bolts of statistical process control. He predicted that, if they followed his guidance, the quality of their products would be the envy of the world in five years.

It came to pass in four years.

Meanwhile American companies, driven by a prosperous marketplace, shifted their focus from quality to rate of production. It was no longer imperative that products be of high quality; there must be many of them to satisfy the high demand of prospering America. Deming’s ideas were forsaken and replaced by emphases on production quotas and rosy financial goals.

Not until his later years, when Japanese automobiles were making serious inroads into the American automobile market, was Deming again called upon to train executives in American industries.

After many years of instructing engineers and managers in the use of process control, Deming formulated Fourteen Points for the Transformation of Management. These Points were the basis of his quality philosophy and he urged that all members of a transforming organization, from the CEO to the night custodian, needed to understand and live the Fourteen Points.

Deming always felt that workers always do their best. Specifically he felt that the usual assumption of management that defects in production were due to ineptitude on the part of workers was erroneous. Defects are caused not by individuals, but by problems in “the system” in Deming’s view.

Deming learned and taught that a company’s complete approach to business had to change if the quality of the company’s product or service was to improve. He knew for this systemic change to occur, the top levels of management must be trained to think in new ways:

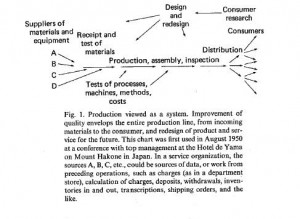

- All aspects of the company—production, sales, engineering, design—plus the suppliers, competitors and customers must be viewed as an integrated whole. Deming’s term was the system. It is this system that must be the focus of management as they assess how best to improve the product rather than blaming a few individuals.

- Statistical process control is a valuable mechanism that can help identify what processes in the system need adjustment.

- Operating a business by focusing on quotas (sales quotas or production quotas, for example) results in poor workmanship or dishonesty on the part of employees to meet the quotas. By focusing instead on providing each individual in the company with high-quality tools and materials as well as premier instruction (not only for their jobs, but for their lives), quality of the product improves and customer loyalty results.

- Improving product quality produces a chain reaction: better quality results in lower costs and higher productivity which lowers prices which increases customer loyalty and market share which allows the company to expand and provide more jobs.

- Rather than compete for a niche in a limited market, cooperation with “competitors” can lead to innovations which in turn expands the market for both (or all) companies.

- Management through fear and intimidation not only discourages employees but also is often damaging to the company. If workers are threatened with “consequences” if quotas aren’t met, for example, then to “meet quotas,” numbers may be fudged or incomplete or faulty products may be shipped. Management may be satisfied, but customers won’t be. Deming advised companies to “drive out fear” in all its forms.

- Working with a single supplier for each item necessary for production improves the quality of the product and can also stimulate innovation. This is contrary to two common practices regarding vendors—awarding contracts to the lowest bidder and second-sourcing. (Second-sourcing is identifying standby vendors and obtaining material from them if the first source has some problem.) Often the material from a second source (or the lowest bidder this year) differs from the regular material and the end product is of lower quality. Once poor-quality product is on the market it is difficult to recover a reputation of producing quality.

- A business should have a purpose that gives them focus through difficult economic times. Quarterly dividends and annual reports pale in comparison to the pursuit of a worthy purpose.

- Including customers and suppliers in the design of new products expands possibilities and can open new markets. It also enhances customer loyalty.

Deming was adamant that his philosophy could not be administered in a piecemeal fashion, but must be embraced fully to be effective. Nonetheless many companies use statistical process control or a few other elements of his teachings without incorporating the fundamentals.

The fundamentals of his philosophy have proven undeniably successful in achieving product quality and long-term financial stability. With adaptations described in subsequent chapters, those same principles can bring improved quality to our personal lives.

Deming’s Fourteen Points for the Transformation of Management can be distilled down to seven principles that can be applied to our personal lives. We will examine one of those principles in each of the next several blog posts.